Selective Laser Sintering is the most widely used rapid manufacturing technology which uses carbon dioxide laser to sinter powder materials and make prototypes or functional parts with complex structures. This technique can process multi-type materials such as polymers, ceramics and tectorial sands, and turn the design into object within a short time, which is particularly suitable for the early-stage assessments of new products and the rapid manufacturing of small-amount functional parts.With the application of SLS combined with foundry technology and CAD model, “wax model” can be manufactured rapidly without dies, which will be used for the manufacturing of metal parts.

S Series Specifications

|

type

|

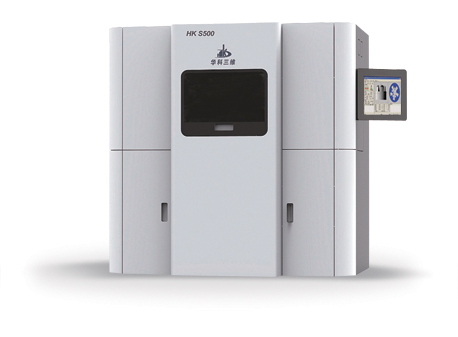

HK S500

|

HK S1000

|

HK S1200

|

HK S1400

|

|

Laser

|

CO2, 55W

|

CO2, 100W

|

CO2 , 100W

|

CO2, Double 100w

CO2, Four 100w

|

|

scanning system

|

dynamic focusing, 8m/s

|

dynamic focusing, 8m/s

|

dynamic focusing, 8m/s

|

dynamic focusing, 8m/s×2

dynamic focusing, 8m/s×4

|

|

Layer thickness

|

0.08-0.3mm

|

|||

|

Part accuracy

|

±0.2mm(L≤200mm)或±0.1%(L≥200mm)

|

|||

|

Forming Room( L×W×H)

|

500mm×500mm

×400mm |

1000mm×1000mm

×600mm |

1200mm×1200mm

×600mm |

1400mm×700mm×500mm

1400mm×1400mm×500mm

|

|

Powder spreading system

|

Powder delivery cylinder on the top with forming working cylinder in the middle

|

|||

|

Material

|

PS,coated sand

|

|||

|

Operating system for installing the application software

|

Windows XP

|

|||

|

Application software

|

HUST 3DP (independent research and development)

|

|||

|

Function

software

|

read STL files directly, on-line slicing function, parameters can be changed at any time during the forming process, such as thickness, scan spacing, scanning mode, etc. ; 3D visualization

|

|||

|

Outline dimension (LxWxH mm)

|

2070mm×1280mm

×2080mm |

2150mm×2170mm

×3100mm |

2350mm×2390mm

×3400mm |

2520mm×1790mm

×2780mm |

Applications and Features:

1. Manufacuring functional parts of PP/PA12 for structure verification,functional tests and prototype assembly directly.

2. The formed prototype can be used as wax moulds and sand core for investment casting.

3. The formed prototype can make Fabrication of dies&moulds,such as silicon rubber mould,metal mould made by cold spray,epoxy resin mould.

4. The entire software is self-developed by our company. We have self-dependent knowledge property right.